A QUICK TRIP TO DETROIT AND A GLIMPSE OF ADDITIVE’S NEXT CHAPTER Thomas Schultz, our Sales Manager, returned from attending […]

A QUICK TRIP TO DETROIT AND A GLIMPSE OF ADDITIVE’S NEXT CHAPTER Thomas Schultz, our Sales Manager, returned from attending […]

New Furnace to Support Annealing, Tempering, and Heat Treatment of Steel and Castings L&L Special Furnace is pleased to announce […]

FOR IN-HOUSE SUPPORT OF SNAP-ON PRODUCTION LINE L&L Special Furnace, a leader in high-quality heat-treating furnaces, is proud to announce […]

FOR HEAT-TREATING DEPARTMENT IN INVESTMENT CASTINGS COMPANY L&L Special Furnace company recently delivered a large floor-standing box furnace to the […]

Receives Two Large Box Furnace Orders L&L Special Furnace Company recently obtained an order for two large front-loading box furnaces […]

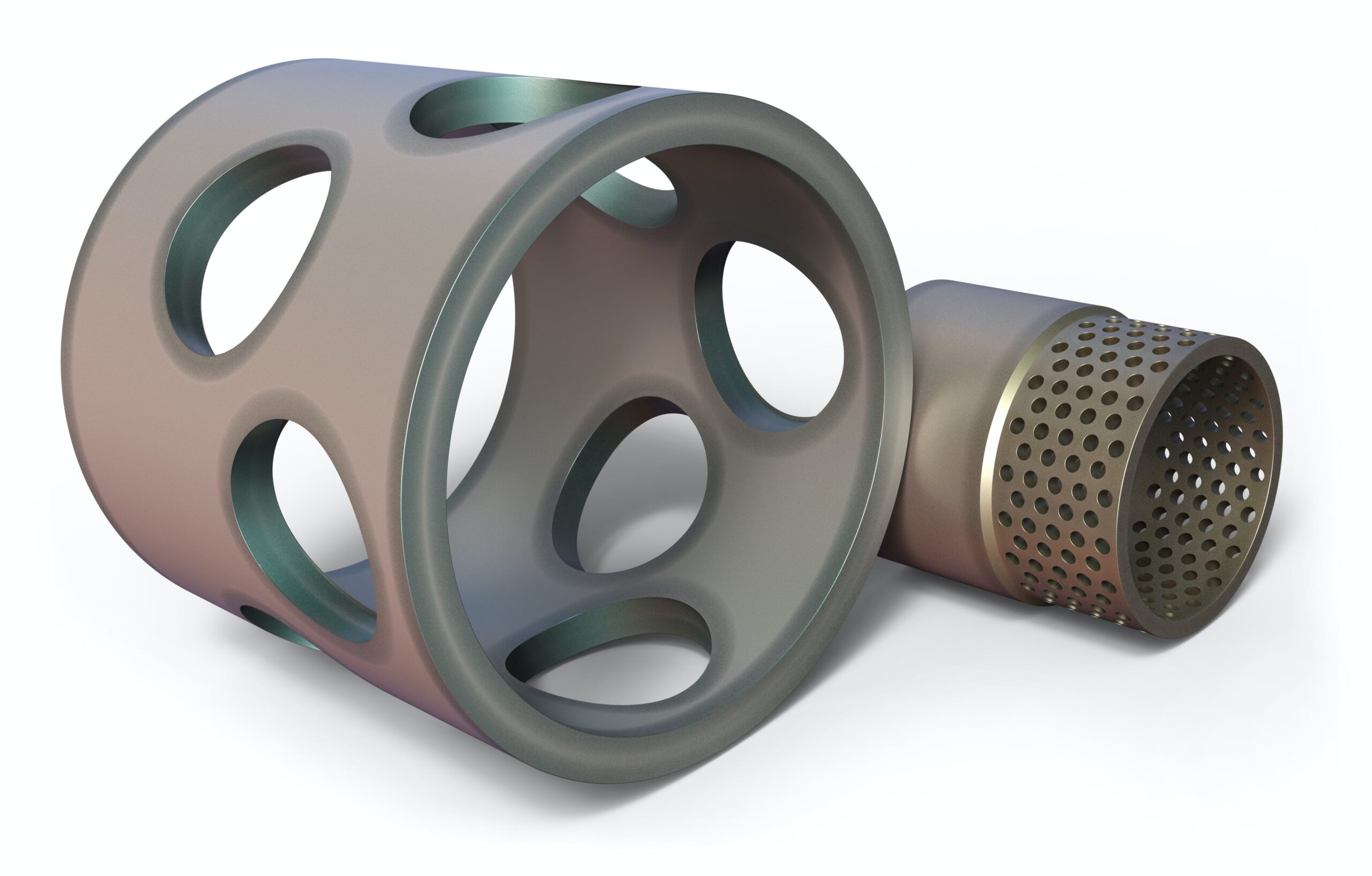

Introduction L&L Special Furnace Co., Inc.’s Sales and Engineering department was approached by a customer in the Additive Manufacturing (AM) […]

Widely Adaptable for Many Different Thermal Applications Since making its initial appearance in the early 1980s, L&L Special Furnace Co.’s […]

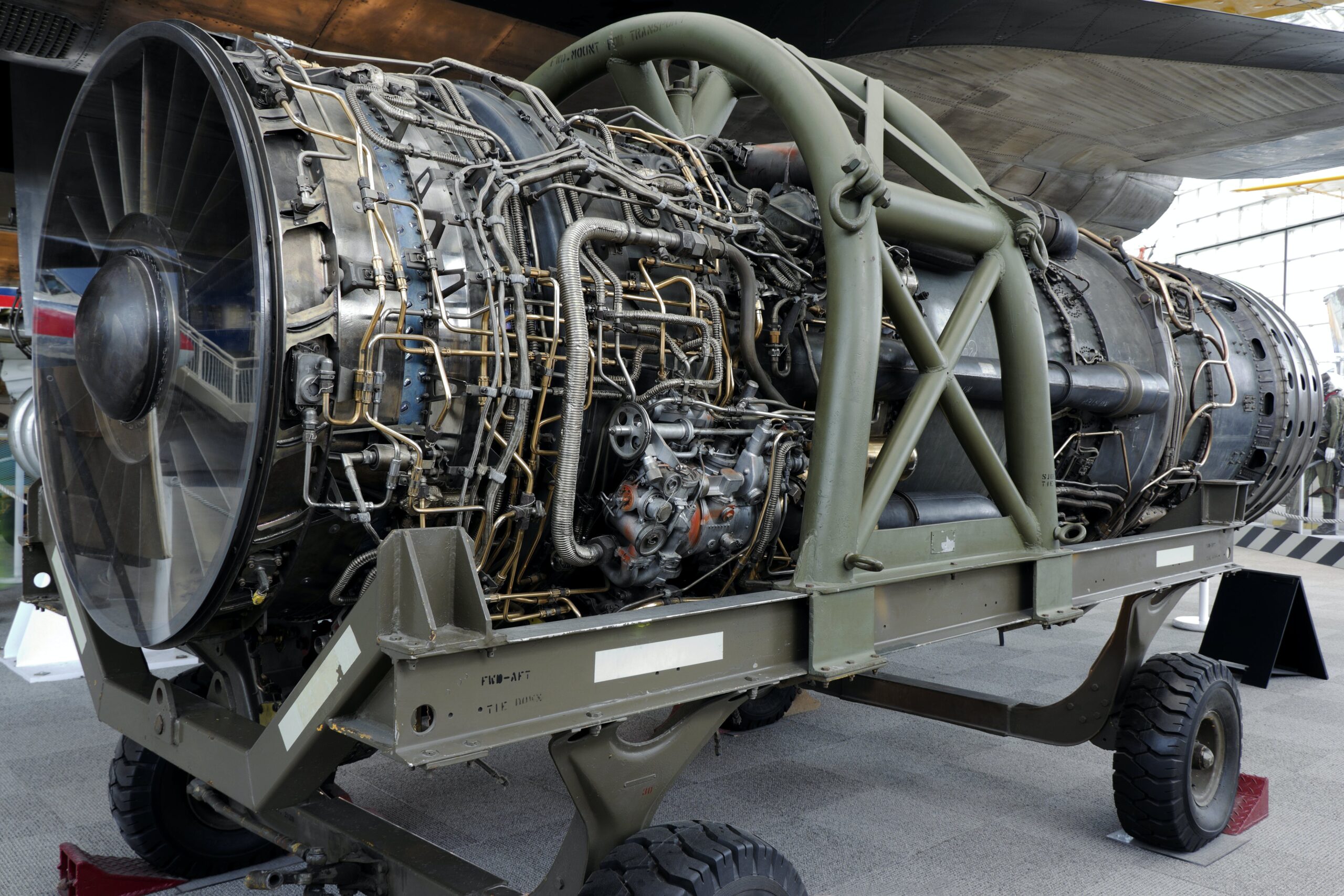

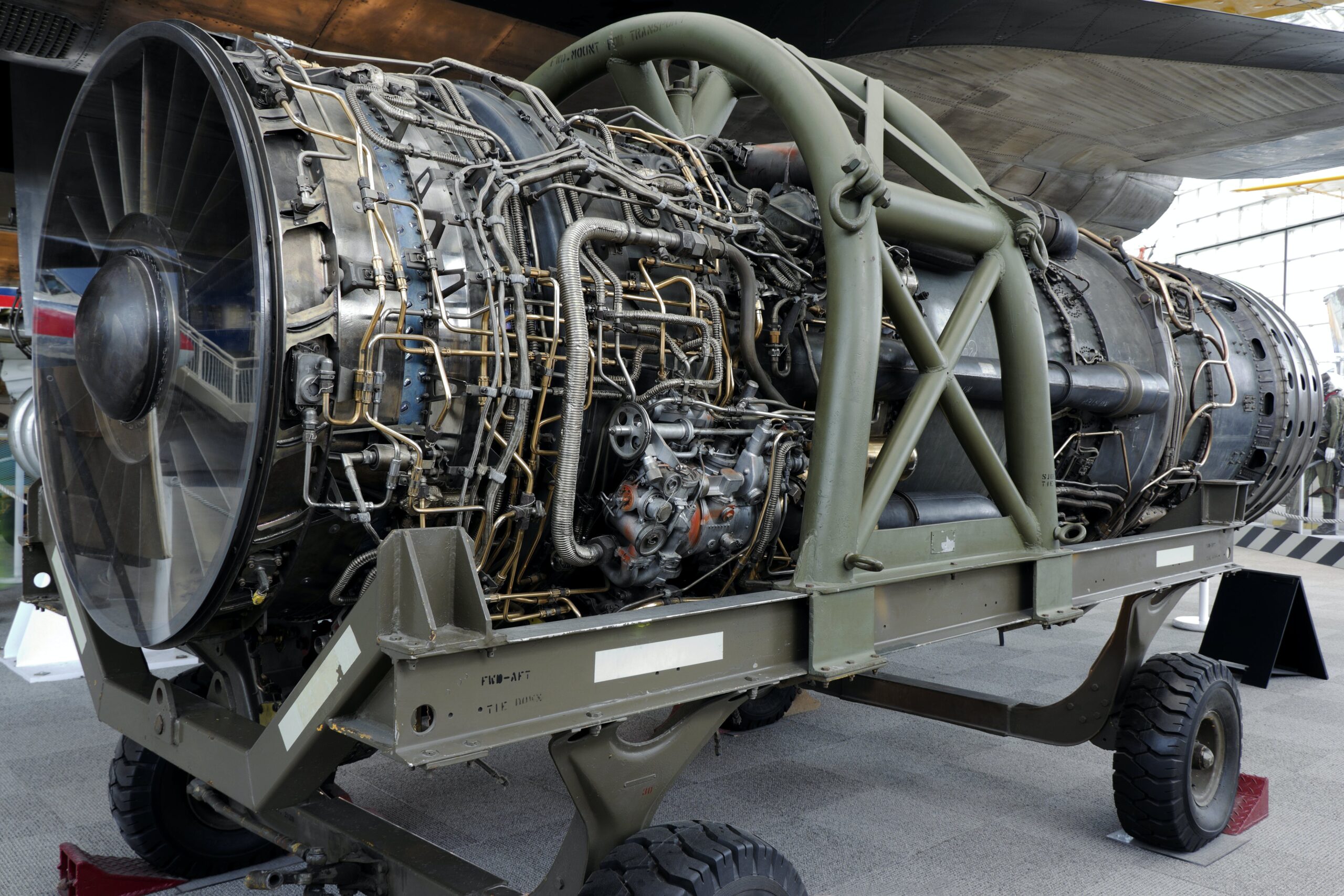

L&L Special Furnace has delivered one of two model XLC3348 furnaces to a leading manufacturer of aerospace components in the […]

L&L Special Furnace has shipped a model XLC3348 retort furnace with an Inconel 602CA alloy retort to a leading manufacturer […]

L&L Special Furnace Ships an Agitated Heated Oil Quench Tank Used for Quenching Various Tool Steels L&L Special Furnace has […]

L&L Ships Fiber-Lined Box Furnace to a Titanium Steel Castings Manufacturer for Aerospace and Gas Turbine Casting Applications L&L Special […]

L&L Special Furnace has delivered a highly uniform box furnace to a distributor of equipment to maintenance repair and overhaul […]

L&L Special Furnace Co. has shipped a dual-chamber heat-treating and tempering furnace to a leading global manufacturer of shopping carts […]

It is with great excitement that we are announcing a change in ownership of L&L Special Furnace Co., Inc. Beginning […]

L&L Special Furnace Company, Inc. has delivered a Model XLC3672 to a Midwest manufacturer of ceramic matrix parts (CMCs). CMCs […]

L&L Special Furnace Company, Inc. has shipped and commissioned a large high-temperature box furnace to a Midwestern U.S. plant starting […]

L&L Special Furnace Co., Inc. has received an order for two atmosphere-controlled retort box furnaces used for de-bindering ceramic matrix […]

L&L Special Furnace Company recently received orders for a floor-standing box furnace for heat-treating saw blades along with a large […]

L&L Special Furnace Co., Inc. has delivered a high-uniformity box furnace to a worldwide, leading valve manufacturer located in the […]

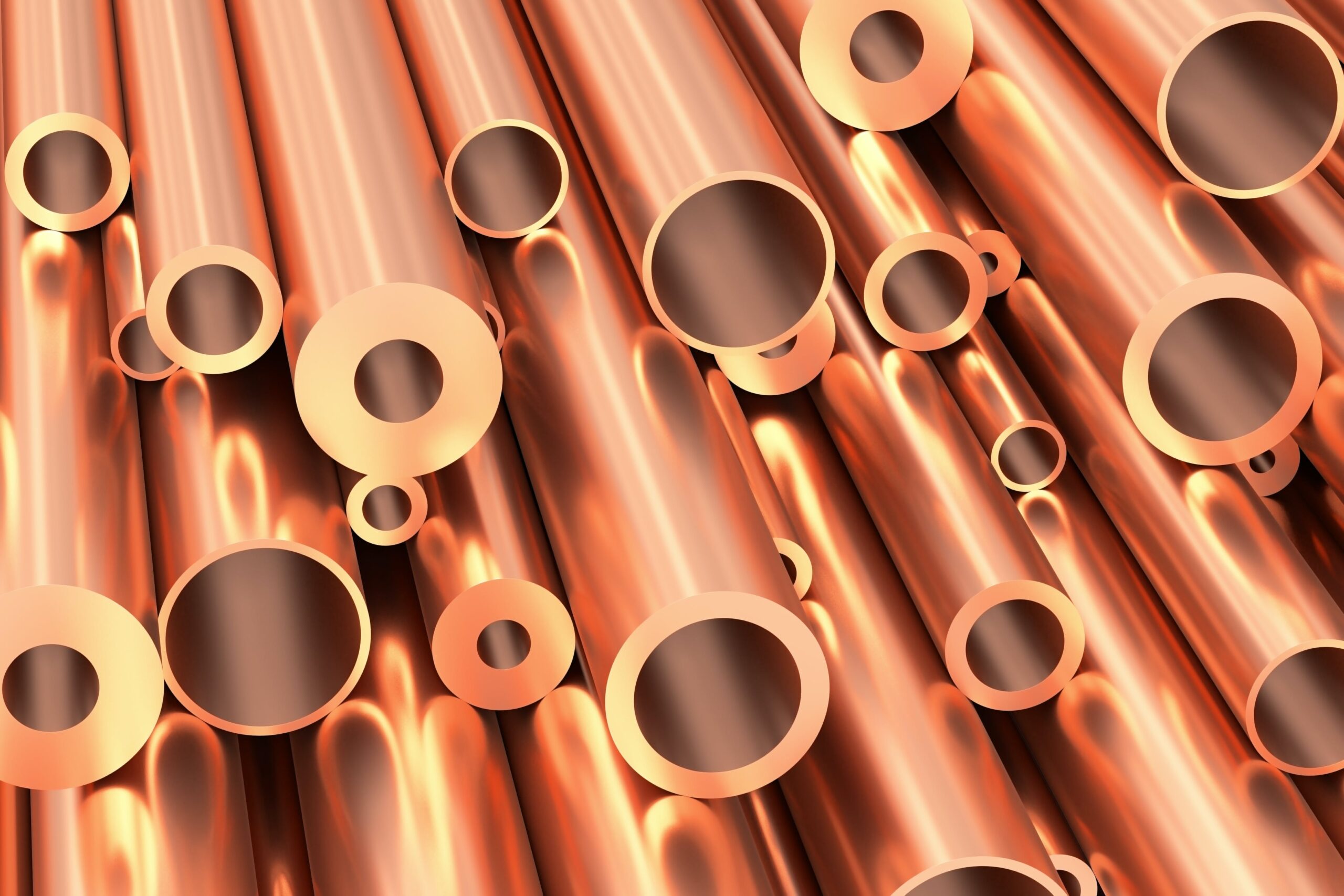

L&L Special Furnace Co., Inc., has shipped a large gas-fired normalizing furnace to a worldwide manufacturer of pipes, tubes, and […]

L&L Special Furnace Co., Inc. has received an order for 10 model GS1714 general-purpose, bench-top lab furnaces. These furnaces will […]

Which hardening process is right for your next project? Nitrocarburizing and carbonitriding represent two case-hardening techniques commonly used today. But […]

L&L Special Furnace Co., Inc. has shipped a floor-standing, high-temperature silicon carbide furnace to a leading worldwide supplier of high-temperature […]

Motor laminations are thin metal sheets that are stacked together to create the core of an electric motor’s stator and […]

L&L Special Furnace Co., Inc., has delivered a high-uniformity box furnace to Soil Lab, a community-based workshop based in Chicago, […]

While traditional forms of metal manufacturing like forging and casting have been around for hundreds of years, there are some […]

L&L Special Furnace Co., Inc. has shipped a second bench-mounted box furnace to a worldwide leading manufacturer of high-purity fused […]

L&L Special Furnace Company has received an order for a large gas-fired, car bottom furnace from a leading manufacturer of […]

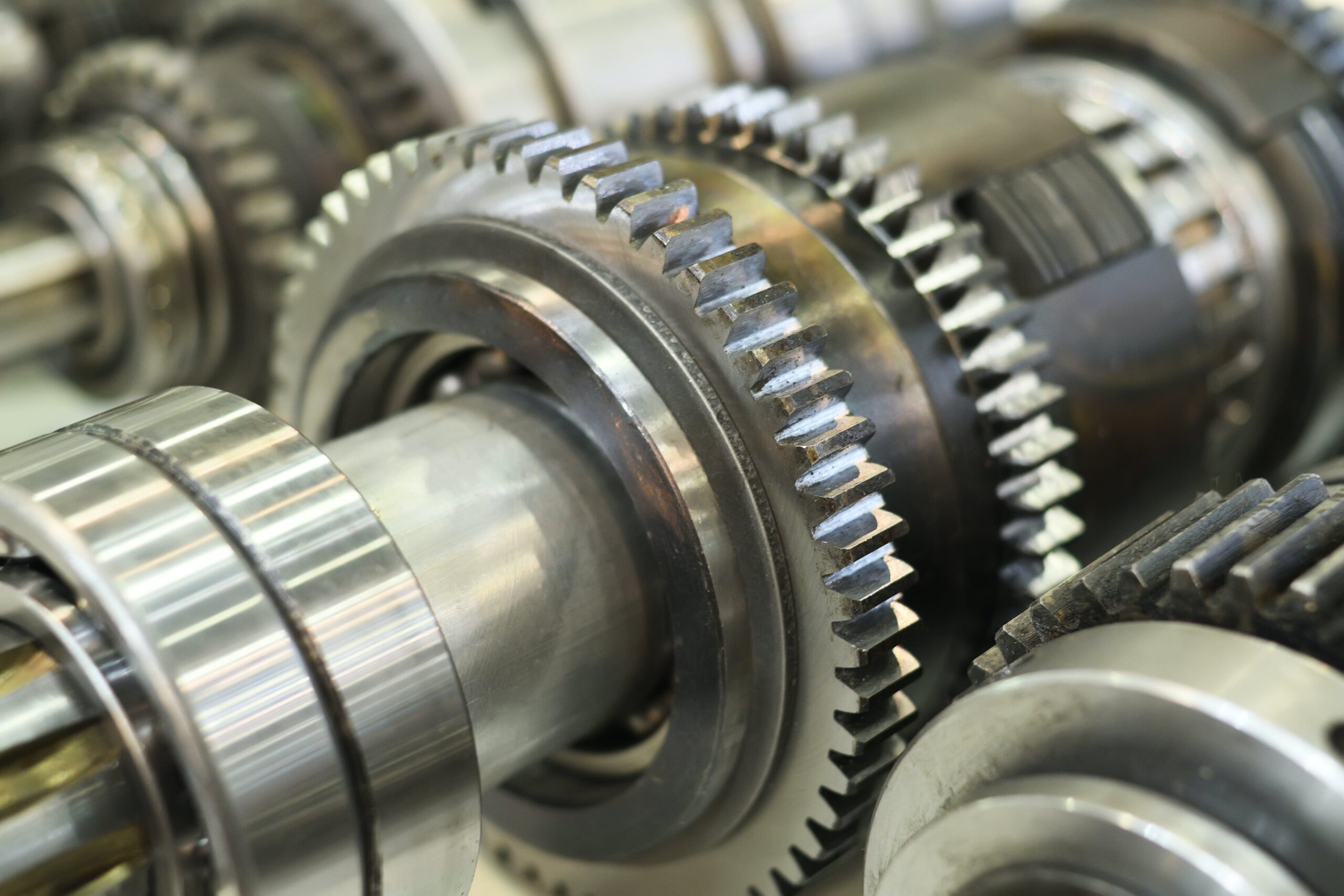

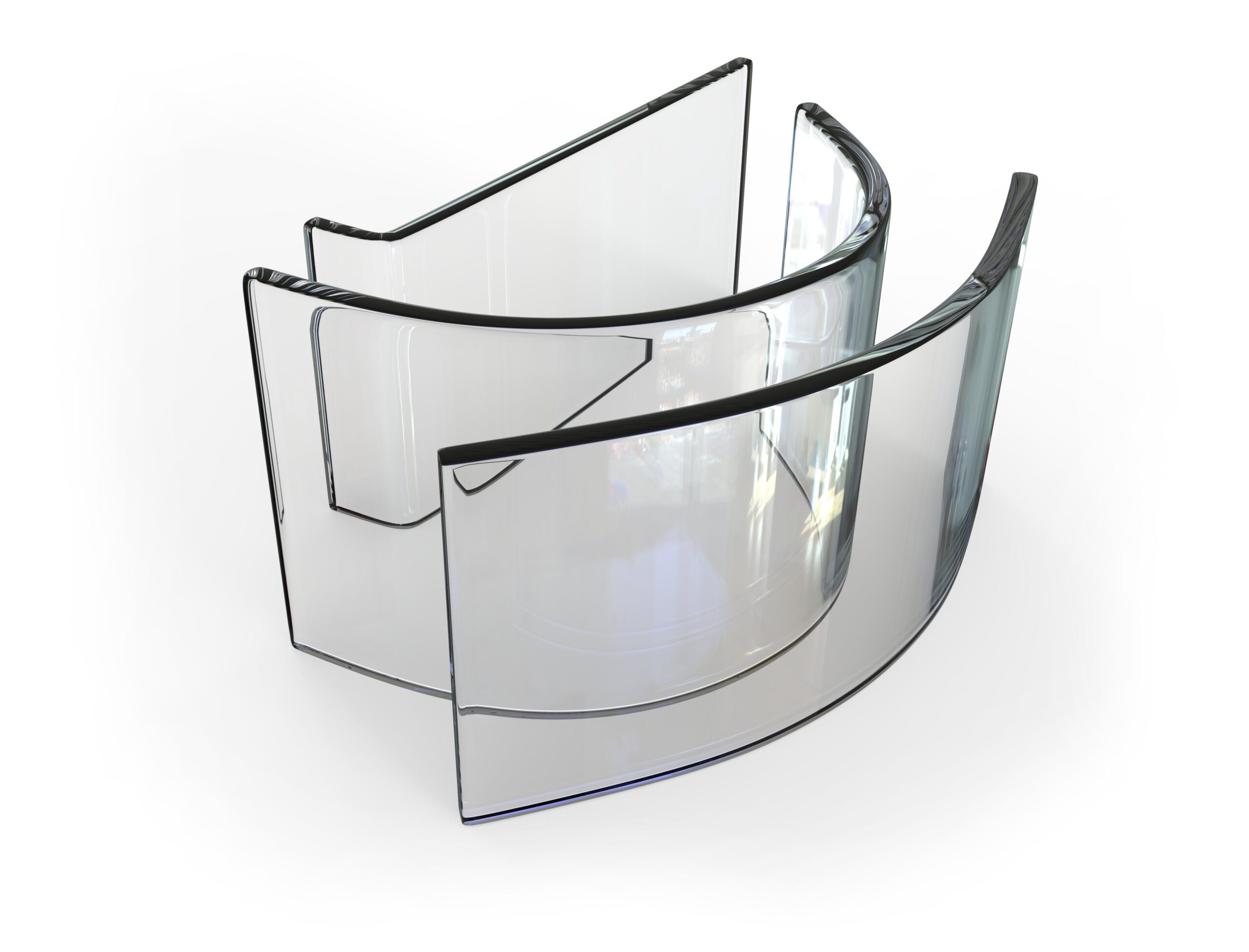

The beauty and elegance of heat-treated steel don’t stop at the metal’s surface; they can also be seen in the […]

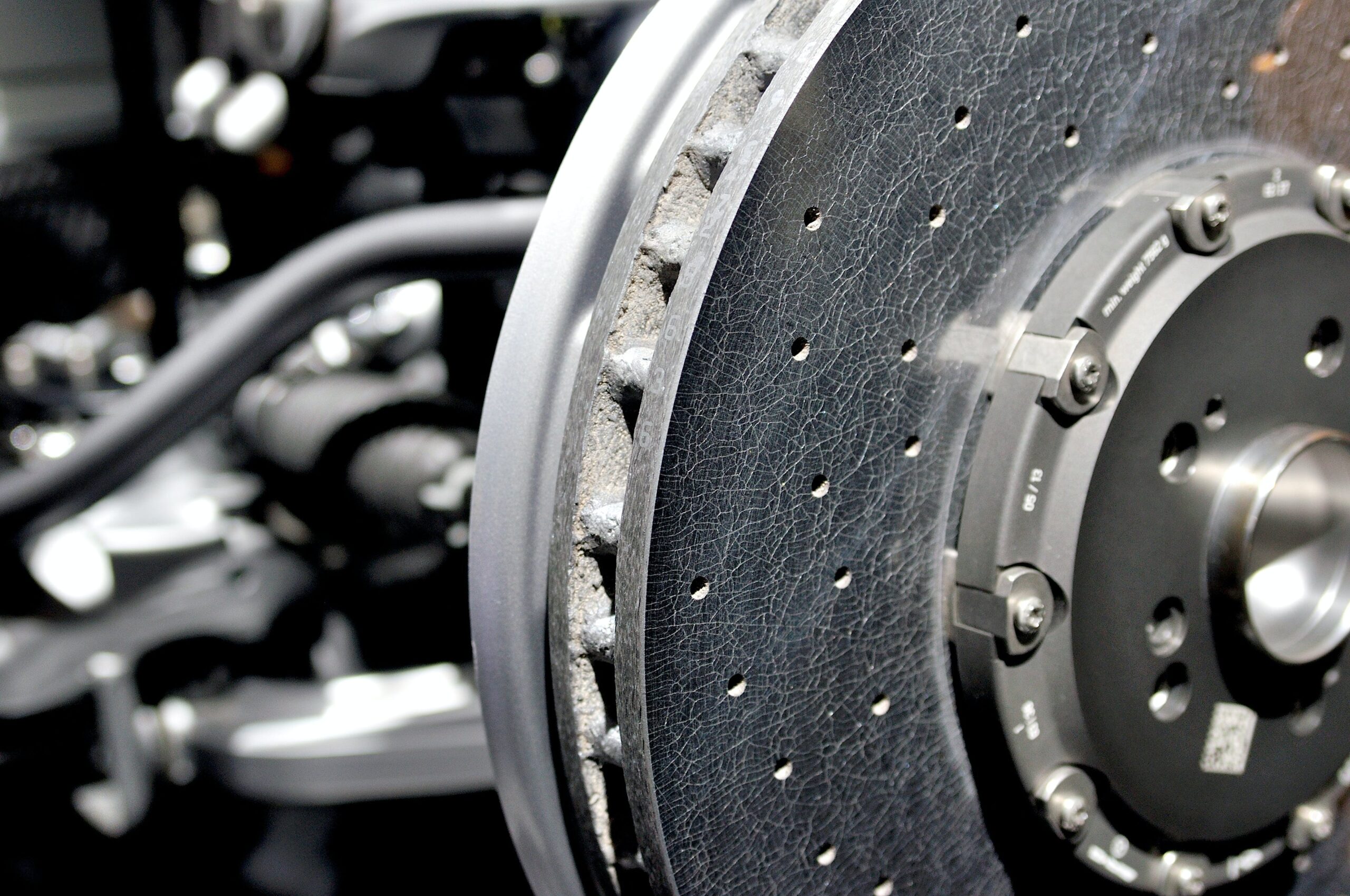

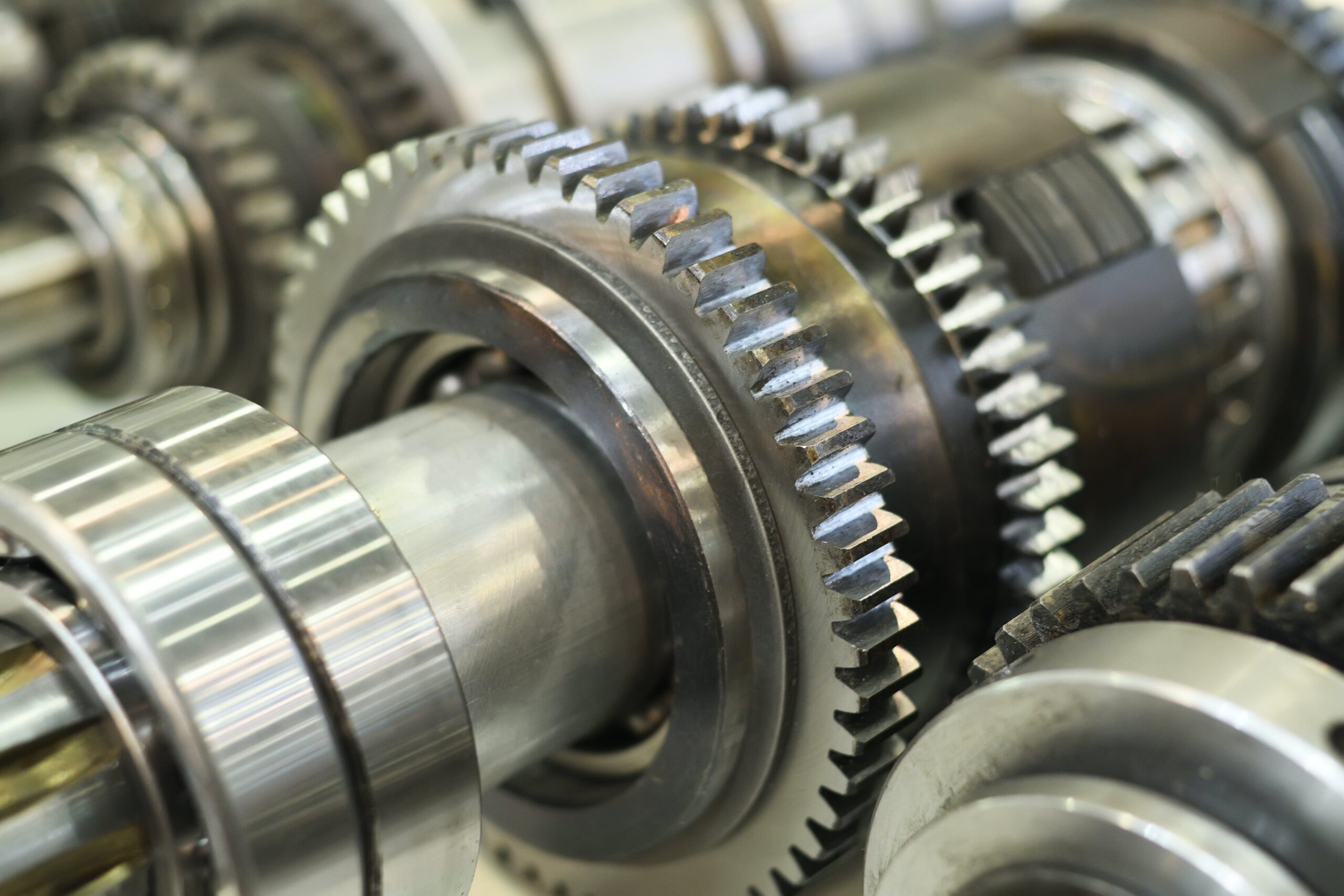

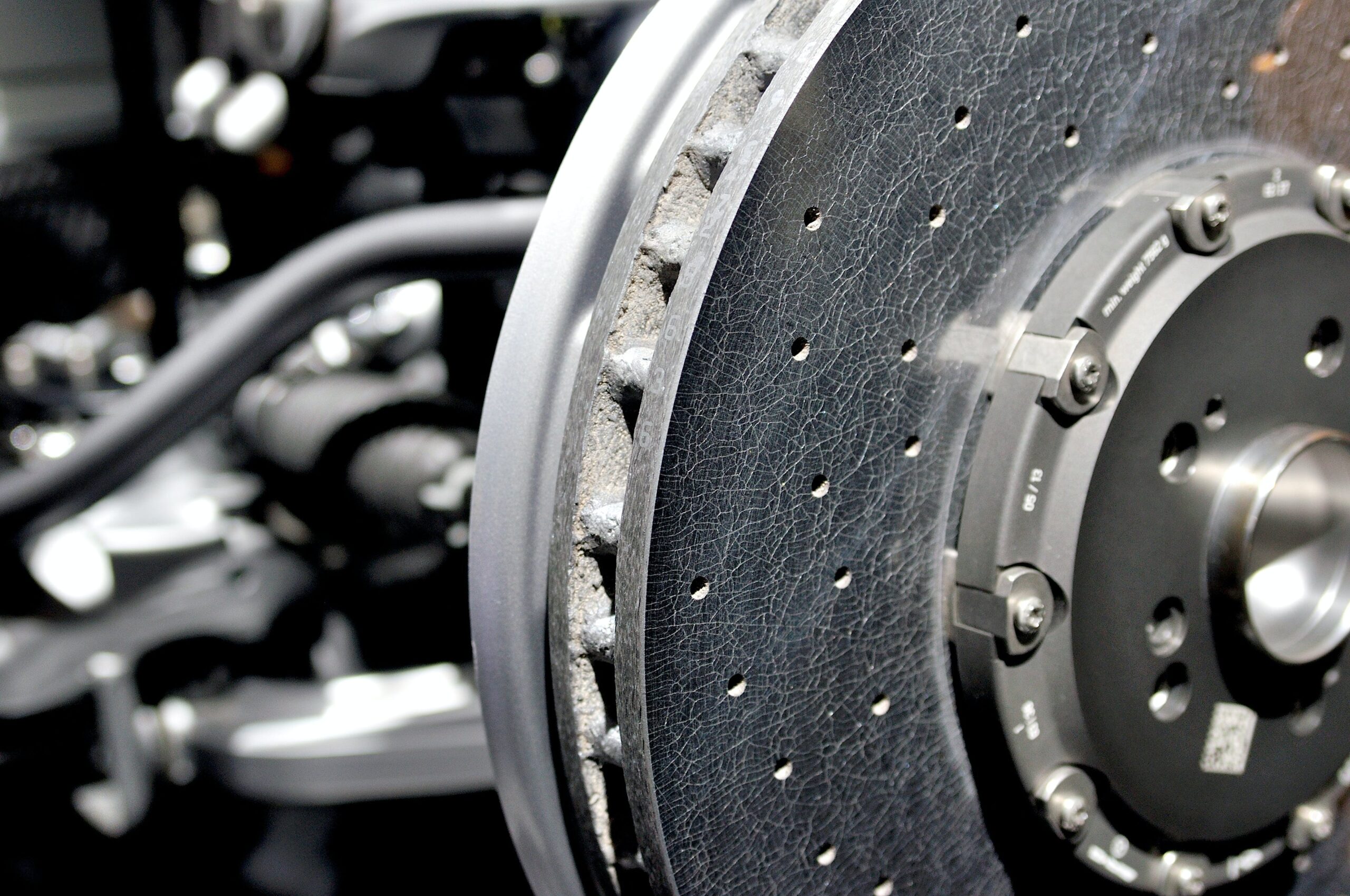

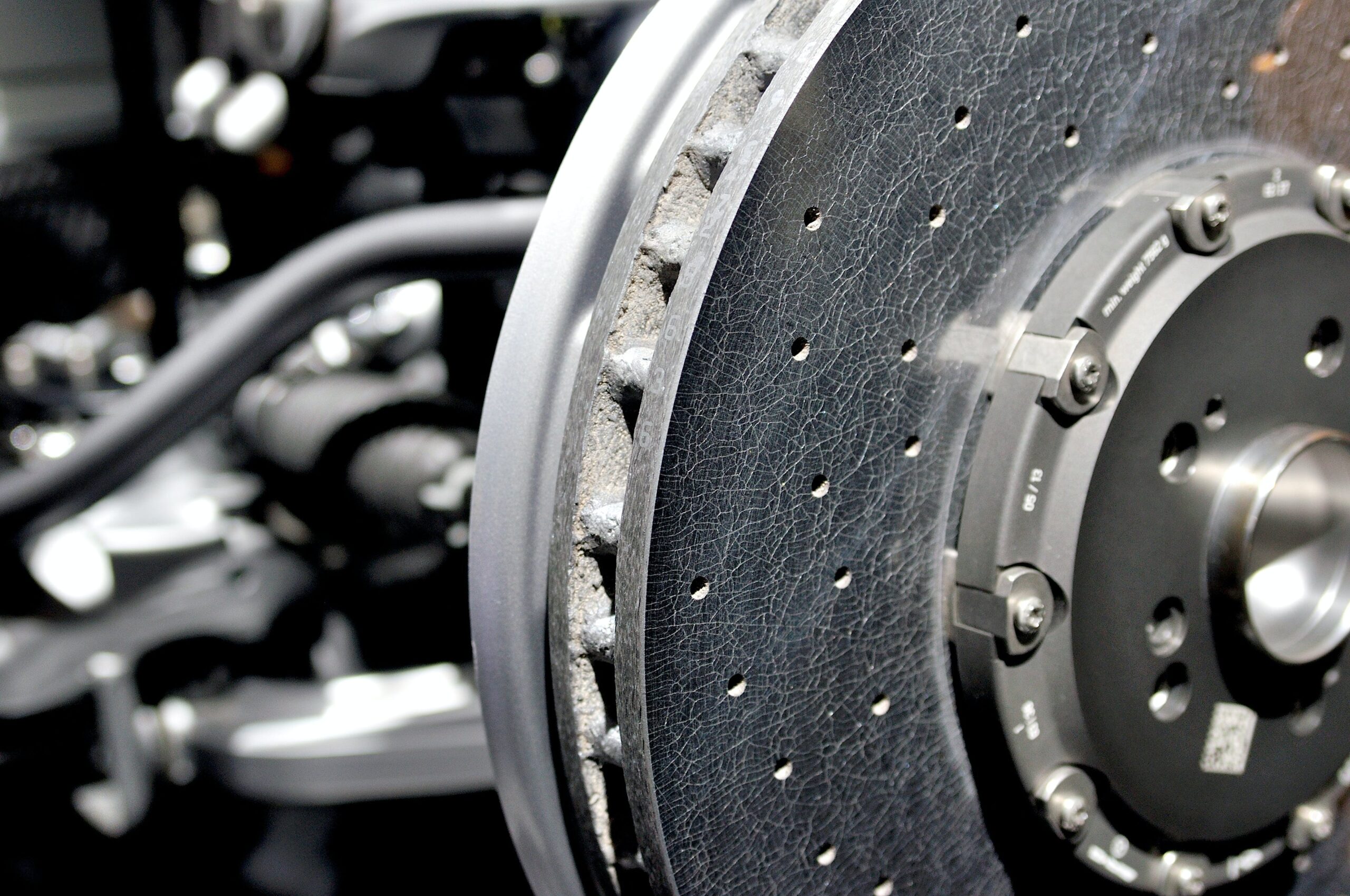

Automotive heat treatment is essential for maintaining the structural integrity of modern cars. Metal components vary in type and quality, […]

Bring Your Heat Treat In House NOW! Don’t Get Caught Flat Footed When Your Business Heats Up!

L&L Special Furnace Company has shipped a floor-standing box furnace used for ceramic coating applications in the aerospace industry to […]

If you own a manufacturing business that produces aluminum parts that require heat treatment, it’s important that you use the […]

L&L Special Furnace Company has shipped a second floor-standing box furnace for heat-treating ceramics and optics used in the medical […]

With a decades-long reputation for designing special industrial furnaces, ovens, kilns, quench tanks, and heat-treating systems, L&L Special Furnace Co., […]

Heat treatments are vital to the manufacturing of both firearms and their ammunition. Many gun parts require heat treatments as […]

L&L Special Furnace Co., Inc. has shipped two Model GS2026 heat-treating furnaces to a manufacturer of brick dies, textured stucco […]

L&L Special Furnace Company has received a second order for a medium-sized floor-standing box furnace that will be used for […]

When it comes to the heat treatment of Aluminum parts, solution heat treatment is one of the most common processes. […]

Injection molding is one of the primary ways to manufacture parts out of powder metal. The main benefit of using […]

L&L Special Furnace Co. has shipped a highly-uniform box furnace to a major aerospace manufacturer located in the southeastern United […]

Using powder metal to manufacture components can be more cost-effective than other manufacturing methods. However, despite being cost-effective, using powder […]

PRECISION, UNIFORMITY, VALUE L&L Special Furnace Co, Inc. has a longstanding reputation for designing special industrial furnaces, ovens, kilns, quench […]

L&L Special Furnace Co., Inc., has shipped a medium-sized, high-temperature box furnace to a government military defense organization located in […]

The National Fire Protection Association (NFPA) is an organization that promotes fire, electrical, and other hazard safety. One of the […]

Brazing copper in a hydrogen atmosphere is used for the creation of strong joints that can withstand high pressures and […]

Quenching is the rapid cooling of hot metal in a liquid or gas medium to preserve certain mechanical qualities it […]

Precipitation hardening, also sometimes referred to as artificial aging, is a heat treatment process used to bring some aluminum alloys […]

L&L Special Furnace Co., Inc. has delivered three multipurpose GS2026 bench mounted box furnaces used to test high-temperature aerospace fasteners. […]

L&L Special Furnace Co., Inc. has manufactured a fourth high-uniformity, pit-style furnace used for annealing. This furnace has been supplied […]

Tempering is a heat treatment process by which steels (and other metals) are given more beneficial properties, usually involving the strengthening of the material.

Carbonitriding is a process by which carbon and nitrogen are introduced to the surface of a steel part. The goal of this process is to form an austenite (above A3) which becomes a martensite matrix microstructure after quenching.

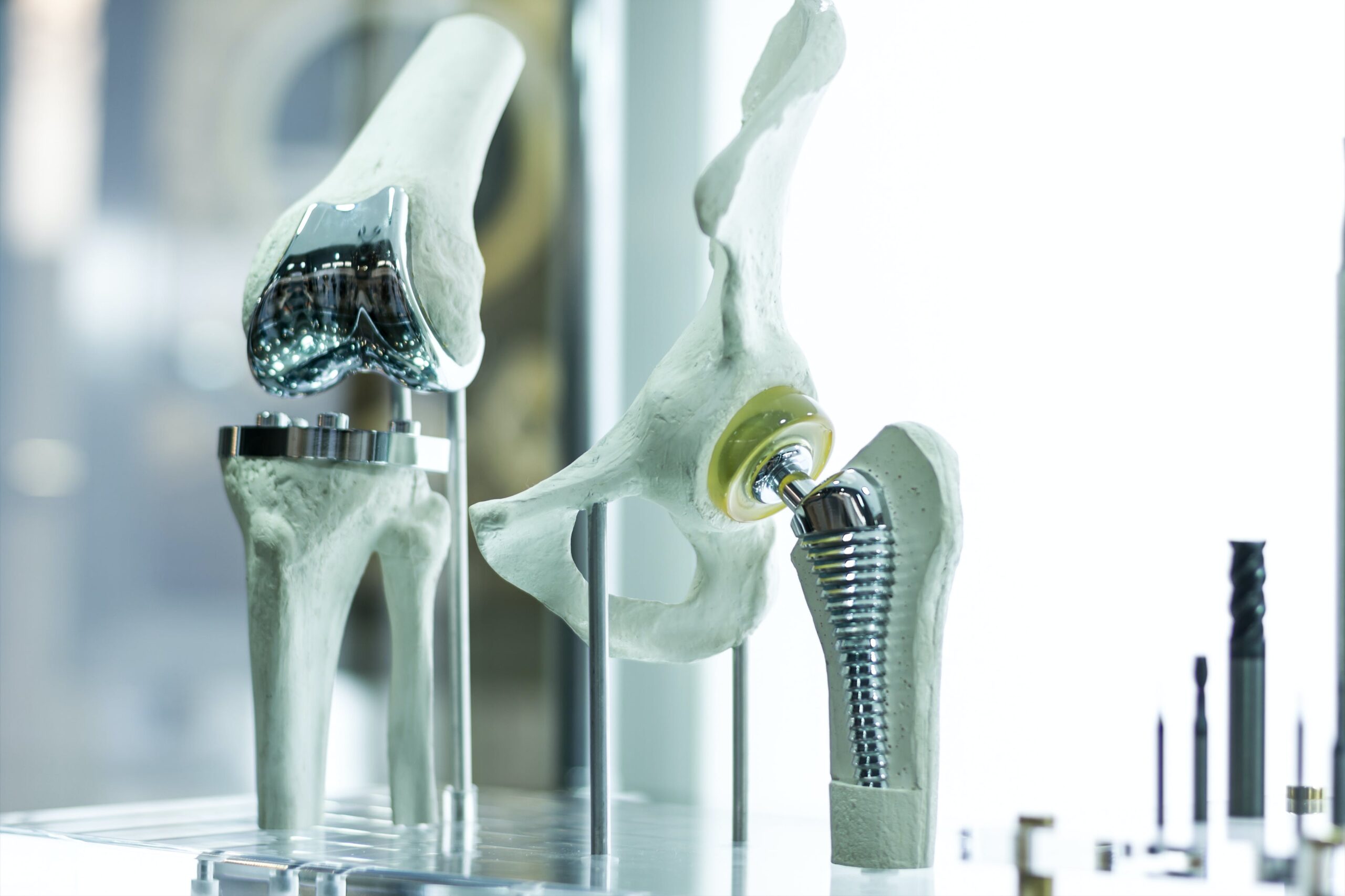

L&L Special Furnace Co, Inc., has shipped a floor standing forging furnace for use in hot forming of medial implant parts along with a floor standing tempering furnace to a manufacturer of medical implant components.

L&L Special Furnace Co, Inc., has shipped five model GS1714 furnaces to a worldwide leading manufacturer of chemicals and chemical coating products used in the medical field. They must be cured at 800°F and the furnaces can also be used for sintering of chemical powders up to 2,200°F.

Annealing is a general term which describes the heating of a metal to a specific temperature, holding it at that […]

L&L Special Furnace Co, Inc. has a longstanding reputation for designing special industrial furnaces, ovens, kilns, quench tanks and heat treating systems. Over these decades of design, production and service, L&L has manufactured some of the best heat treating furnaces, ovens and quenching equipment in the world.

L&L Special Furnace Co, Inc., has shipped a Model FB1046 floor-standing box furnace to a worldwide leader of high tech aerospace and associated components located in the Southeastern United States. The furnace will be used for processing aerospace parts and various thermal applications.

L&L Special Furnace Co., Inc. has shipped and installed a retort box furnace to a worldwide leader of aerospace components in the southern US. The furnace is used to de-binder ceramic matrix composite components deployed in the aircraft industry.

L&L Special Furnace Co, Inc. has shipped the 5th Model GS1714 furnace to a leading manufacturer of calcium phosphate materials used for medical devices.

Both batch processing and flow control are important terms to know if you are involved in the manufacturing industry. The […]

Many heat treatment processes – including bright annealing, sintering, and carbonitriding – require a highly controlled atmosphere in order for […]

L&L Special Furnace Co., Inc. has announced a newly designed catalog describing our full line of furnaces, ovens and quench […]

L&L Special Furnace Co, Inc., has shipped a dual chamber heat treating furnace to a southeastern US manufacturer of various […]

The process we know as additive manufacturing (AM) may seem new, but it has actually been around for about thirty […]

L&L Special Furnace Co., Inc. has shipped a floor-standing furnace to a worldwide leader of high tech ceramics and associated […]

When the goal for a part is the longest possible lifecycle and highest performance while operating under high temperatures, in […]

L&L Special Furnace Co., Inc. has received an order for a large retort box furnace used for de-bindering ceramic composite […]

L&L Special Furnace Co., Inc., has supplied a custom designed and manufactured oil quench tank to a metal stamping manufacturer […]

Here is model DRQ246 under factory test, verifying manual load manipulation and timing from solution heating to quench.

Aluminum heat treatment is a process by which the strength and hardness of a specific subset of aluminum alloys, namely […]

Since the early days of flight, aluminum in many forms has been used in the manufacture of aircraft. Aluminum is […]

L&L Special Furnace Co., Inc., attended and exhibited at the Furnaces North America show in Indianapolis, IN. FNA 2018 is […]

L&L Special Furnace Co., Inc., has supplied an electric box furnace to a plant located in Louisiana that is a […]

Composite materials are comprised of at least two parts: the reinforcement, which provides special mechanical properties such as stiffness or strength, and the matrix material, which holds everything together.

L&L Special Furnace Co, Inc., has supplied an electric box furnace to a Midwestern engine manufacturer that produces parts for […]

L&L Special Furnace Co., Inc. industrial box furnaces are a cut above the competition because we go the extra mile […]

L&L Special Furnace Company has supplied two electric box furnaces to a Midwestern machine manufacturer that builds high-speed cutting equipment, […]

Precision, uniformity and value in everything we build and sell. L&L Special Furnace Co. has been in business for decades, […]

L&L Special Furnace Co., Inc. has commissioned a large resistance box furnace and quench tank in New Zealand for a […]

Overview The heat treatment of tool steel is one of the most important aspects of the final tool. Without proper […]

L&L Special Furnace Co., Inc. has shipped a retort furnace to a northeastern US manufacturer of motor laminations. The laminations […]

L&L Special Furnace Co., Inc. has delivered an intermediate-sized front-loading box furnace that will be used by the Canadian Government […]

L&L Special Furnace Co., Inc., is excited about our new website launch and the amount of detailed and process-oriented information […]

L&L Special Furnace Co., Inc. has released a new four-page brochure describing our line of general purpose electric heat treating […]

L&L Special Furnace Co., Inc. has manufactured a highly uniform box furnace that hardens tool steel used to manufacture decking […]

L&L Special Furnace Co. Inc. manufactured a highly uniform box furnace that hardens tool steel used to manufacture decking fasteners […]

L&L Special Furnace Co., Inc. has delivered a floor standing dual chamber box furnace to an aircraft maintenance repair and […]

On April 12, 1981, when the first space shuttle lifted from its launching pad in Cape Canaveral, Fla., the employees […]

L&L Special Furnace Co., Inc. has manufactured two Model DRQ2436 high-uniformity annealing furnaces with semi-automated quench tanks, quench media coolers […]

L&L Special Furnace Co., Inc. has manufactured a third high uniformity pit-style furnace used for annealing. This furnace has been […]

L&L Special Furnace Co., Inc. has manufactured a high uniformity box furnace used for hydrogen annealing. The furnace has been […]

L&L Special Furnace Co., Inc. has manufactured a high uniformity, dual chamber box furnace used for solution heat treating of […]