Since the early days of flight, aluminum in many forms has been used in the manufacture of aircraft. Aluminum is a lightweight structural material that can be strengthened through alloying and, depending upon composition, further strengthened by heat treatment and/or cold working.

Among its advantages for specific applications are low density, high strength-to-weight ratio, good corrosion resistance, ease of fabrication, and diversity of form. These attributes, along with its relatively low material cost, are strong factors that make aluminum the most common material used in both aerospace and automotive industries today.

Heat Treatable Grades of Aluminum

There are various grades of aluminum, each with properties that define what types of applications they can be used for. Not all grades of aluminum are heat-treatable, however. The heat treatable grades of aluminum alloys include the 2XXX, 6XXX, 7XXX, and 8XXX series. Each of these series has a unique set of characteristics that are enhanced by thermal processing.

There are various grades of aluminum, each with properties that define what types of applications they can be used for. Not all grades of aluminum are heat-treatable, however. The heat treatable grades of aluminum alloys include the 2XXX, 6XXX, 7XXX, and 8XXX series. Each of these series has a unique set of characteristics that are enhanced by thermal processing.

The 2XXX series has copper as its primary alloying element, which gives it additional strength, and is a commonly used aircraft alloy. The 6XXX series include silicon and magnesium in the alloy, which provides even better corrosion resistance that makes it very well adapted for use in automobile production. The 7XXX series includes zinc and magnesium and either chromium or copper. This combination of alloying elements makes extremely high strength possible, and this series is used extensively in the aerospace industry. The 8XXX series are alloyed with iron, silicon, vanadium, and copper. This series is also widely used in aerospace.

Aluminum Alloy Heat Treatment Designations

Each series number is followed by 3 additional numbers (replacing the “XXX” above) that further specify the alloy composition and thermal processing capabilities of each specific material. In addition, a temper designation appears as a hyphenated suffix to the basic alloy number. An example would be 7075-T73 where -T73 is the temper designation. Four basic temper designations are used for aluminum alloys. They are:

- F: as fabricated

- 0: annealed, or full soft

- H: strain hardened

- T: thermally treated

A fifth designation, -W, is used to describe an as-quenched condition that lies somewhere between solution heat treatment and artificial or room temperature.

Strain hardened aluminum alloys with the H designation typically include one or two more digits. H1 is strain hardened without thermal treatment, H2 is strain hardened and partially annealed, H3 is strain hardened and then stabilized by low temperature heating. The second digit represents the degree of hardness obtained by strain hardening. For example, HX2 is ¼ hard, HX4 is ½ hard, HX6 is ¾ hard, and HX8 is full hard. A designation of HX9 would represent extra hard.

The T designation means that the aluminum has been heat treated to produce a stable temper. The T can appear as TX, TXX, or TXXX, with the digits providing detail as to what heat treatment process and quenches were involved. For example, T6 means solution heat treated and artificially aged, while T4 means solution heat treated and naturally aged.

AMS2750E

There are various types of aluminum heat treating; each one has a designated process and specific criteria that must be strictly adhered to. The global pyrometry specification that was written for aluminum and many other metals used in aerospace and automotive applications is AMS2750E (Aerospace Material Specifications). It was issued by SAE International and used by Nadcap in certification and auditing of heat treating equipment used in aviation and automotive manufacturing and production.

There are various types of aluminum heat treating; each one has a designated process and specific criteria that must be strictly adhered to. The global pyrometry specification that was written for aluminum and many other metals used in aerospace and automotive applications is AMS2750E (Aerospace Material Specifications). It was issued by SAE International and used by Nadcap in certification and auditing of heat treating equipment used in aviation and automotive manufacturing and production.

This specification was written to ensure that critical processes are kept within strict guidelines as delineated in this specification. Norm compliance to the AMS2750E standard means that the quality standard of the components manufactured can be reproduced in series. This is vitally important for components whose failure could not only cost thousands of dollars but could also cost lives.

Factors for AMS2750E Compliance

One of the key aspects of compliance to this pyrometry standard is temperature uniformity in the workspace, which must be measured through the prescribed placement of thermocouples in a survey (TUS.). These thermocouples must not only be placed correctly but also be of the correct type and be calibrated before use. Where the thermocouples are placed depends on various factors, such as whether or not the oven uses recirculating flows or if it is a vacuum furnace.

One of the key aspects of compliance to this pyrometry standard is temperature uniformity in the workspace, which must be measured through the prescribed placement of thermocouples in a survey (TUS.). These thermocouples must not only be placed correctly but also be of the correct type and be calibrated before use. Where the thermocouples are placed depends on various factors, such as whether or not the oven uses recirculating flows or if it is a vacuum furnace.

Naturally, there will be uncertainty in the temperature measurements. The level of uncertainty is a function of the wire used, the design of both the probes and the connectors, the lead wire (if used), the accuracy of the furnace controller, and any algorithms used internally by the controller.

Also, the thermocouples are not the only item that needs to be calibrated. It is also important that the measurement system from the controller all the way through to the thermocouple be calibrated.

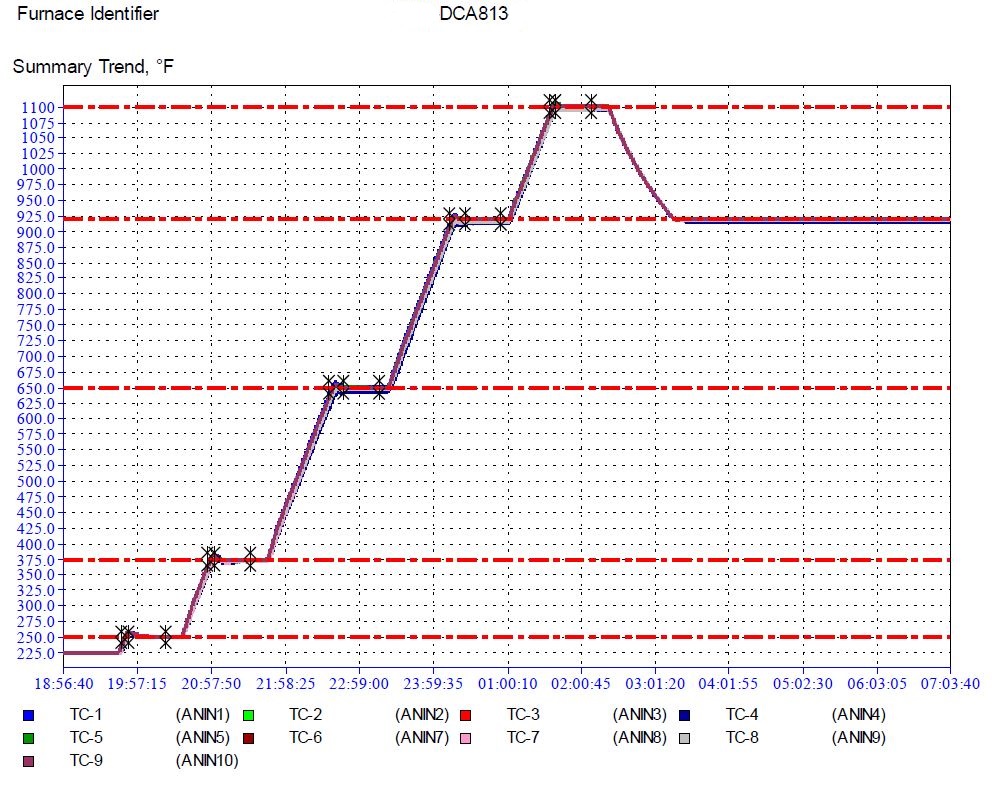

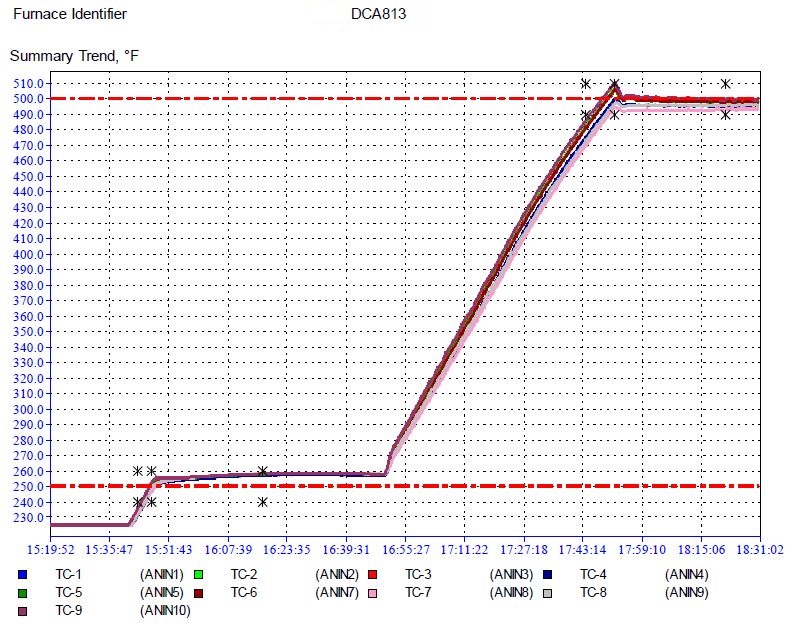

The accuracy of the system must be inspected on a regular basis, and the inspection cycles (and their results) must be thoroughly documented. The inspection of instrumentation is referred to as a System Accuracy Test (SAT). TUS must also be tested on a regular basis and documented as well.

Furnace Requirements for AMS2750E Compliance

The ability to meet AMS2750E standards starts with the design of the furnace. The materials used for constructing the furnace are a major factor, as is the size, type, and location of heaters. Insulation must be properly installed to promote uniform heating and, of course, to prevent the loss of heat.

Thermocouples must be placed to accurately characterize the heating process and the temperature distribution within the oven. Controllers also play a very key role. And not only does this involve the type and accuracy of the controller, but also any internal algorithms that it uses to either read thermocouple temperatures or control the aluminum heat treating processes within the oven itself.

L&L Aviation Pyrometry Package

L&L Special Furnace Co., Inc. has a pyrometry package available for all furnaces that allows our customers to easily measure and maintain the thermal performance of our furnaces in accordance with AMS2750E. This package was designed with not only the AMS2750E standard in mind, but for whoever is responsible for performing the calibration, tests, and audits that it requires.

L&L Special Furnace Co., Inc. has a pyrometry package available for all furnaces that allows our customers to easily measure and maintain the thermal performance of our furnaces in accordance with AMS2750E. This package was designed with not only the AMS2750E standard in mind, but for whoever is responsible for performing the calibration, tests, and audits that it requires.

One of the critical aspects of AMS2750E involves the operation, location, and even selection of thermocouples used for monitoring the temperature distribution inside the oven. L&L provides a thermocouple inlet tube which allows for TUS thermocouples to be inserted into the furnace without compromising the door seal. There are thermocouple reference ports located within 2” of each system thermocouple to perform system accuracy tests (SAT).

There are also thermocouple ports located in the best possible representation of the furnace’s effective work zone. These ports are extremely important and allow for recording of the high and low thermocouple readings as indicated by the most recent temperature uniformity survey (TUS).

All this instrumentation plugs into the main control thermocouple jack panel which in turn is wired to the systems temperature recorder. All data obtained is logged and kept in electronic encrypted format. These files can easily be transferred and shared to analyze the thermal data. L&L’s aviation pyrometry package is a must-have tool for critical temperature processing needs.

L&L Furnaces Used for Aluminum Heat Treating

At L&L Special Furnace Co., Inc., we offer several different series of furnaces that are ideal for the heat treatment of aluminum, including the following:

- VB series of bench mounted recirculating 1300°F (700°C) tempering oven

- GS1714A from the GS series of smaller furnaces which are typically in stock for immediate shipment

- DV/DR series of heavy duty floor standing gas or electric recirculating 1300°F (700°C) tempering ovens

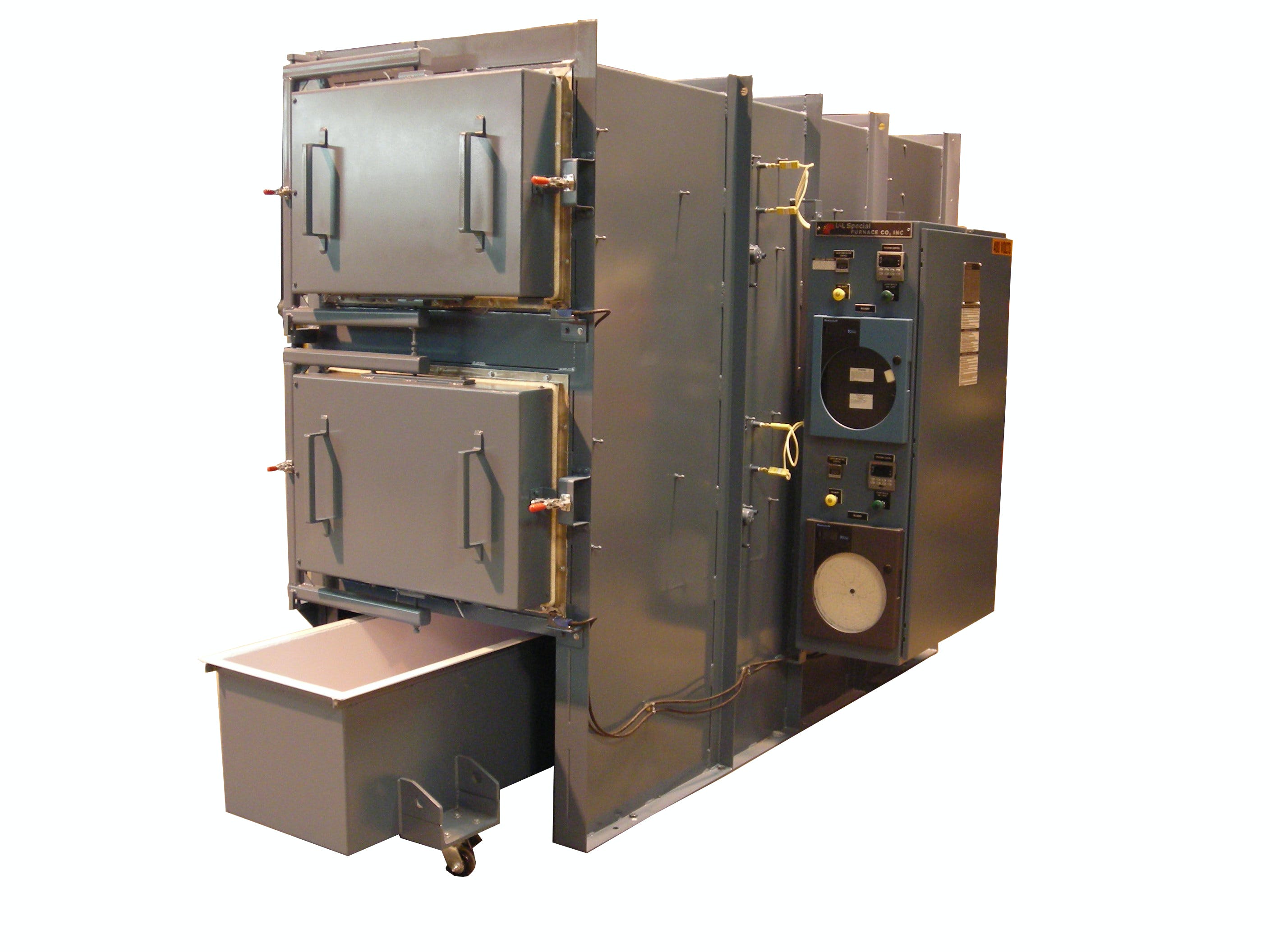

- DCA series of dual chamber aluminum heat treating ovens 1100°F (593°C) / 400°F (260°C)

- DRQ Series of DRQ2436 high-uniformity annealing furnaces with semi-automated quench tanks, quench media coolers and a centralized wash station

In addition, a variety of options are available for our furnaces beyond the aviation pyrometry package already mentioned.

Aluminum Heat Treating and Compliance with AMS2750E

Aluminum heat treating for components used in industries such as aerospace and automotive involve compliance with AMS2750E. Achieving compliance involves calibration and repeated testing but starts with a well-designed furnace with accurate controls and uniform heating. An ideal solution for manufacturers that perform aluminum heat treating is a high quality oven designed with AMS2750E in mind along with a pyrometry package to support the calibration, testing, and documentation that is required. L&L Special Furnace Co, Inc., offers both.

Contact L&L for Aluminum Heat Treating Furnaces

At L&L, we understand that the materials you place in a heat treatment furnace often costs thousands of dollars and there is absolutely no room for error in the processing. That’s why we are committed to providing precise temperature control, highly accurate controllers, and uniform heating in each of our ovens. We have been designing and manufacturing heat treatment furnaces for decades, which means we also realize that off-the-shelf designs don’t work for all our customers. Our experienced, knowledgeable staff will work with you to put together an oven that meets your needs, no matter how exacting they may be.

At L&L, we understand that the materials you place in a heat treatment furnace often costs thousands of dollars and there is absolutely no room for error in the processing. That’s why we are committed to providing precise temperature control, highly accurate controllers, and uniform heating in each of our ovens. We have been designing and manufacturing heat treatment furnaces for decades, which means we also realize that off-the-shelf designs don’t work for all our customers. Our experienced, knowledgeable staff will work with you to put together an oven that meets your needs, no matter how exacting they may be.

Contact us today at L&L to request a quote, and let us help you setup an AMS2750E compliant aluminum heat treatment furnace!