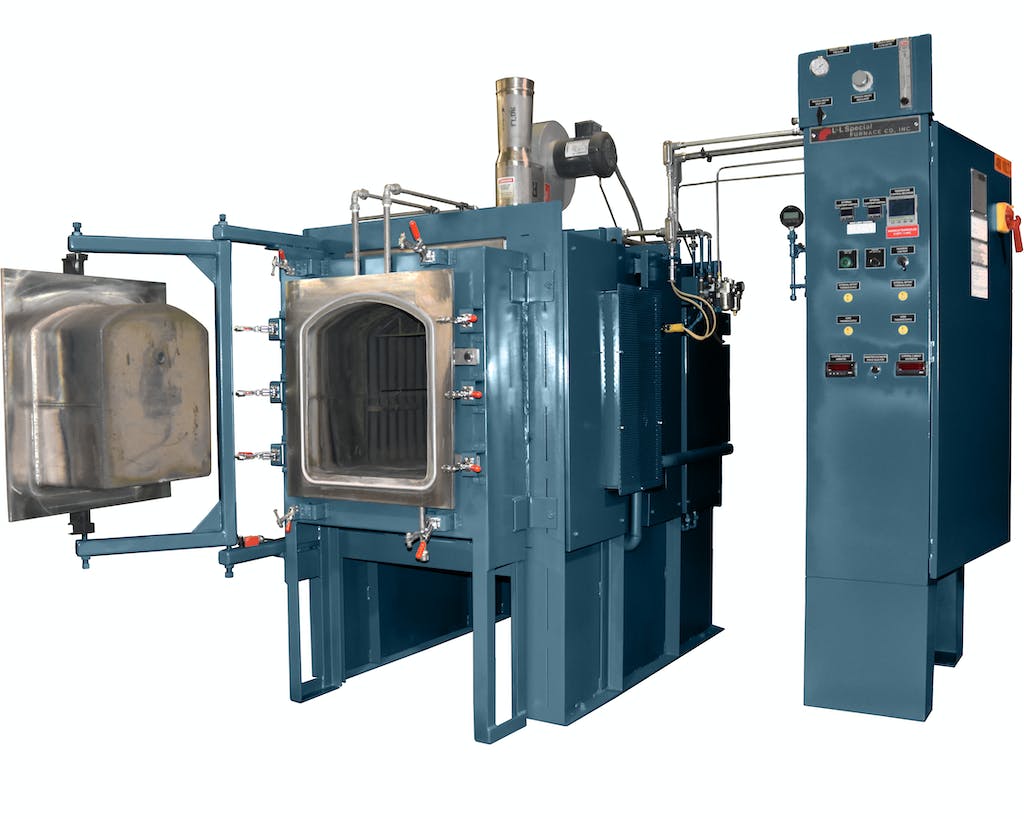

ELECTRICAL BOX RETORT FURNACE INSTALLED FOR DE-BINDERING CERAMIC COMPOSITES

L&L Special Furnace Co., Inc. has shipped and installed a retort box furnace to a worldwide leader of aerospace components in the southern US. The furnace is used to de-binder ceramic matrix composite components deployed in the aircraft industry.

The main function of the furnace is to remove all organics and other materials used in the product prior to placing it in a high-fire vacuum chamber. This de-bindering process is extremely important and allows for a finished product that is not only very strong but also lightweight.

The XLC524 has a work zone of 9” wide by 9” high by 18” deep. It has a temperature gradient of ±20°F at 1,100°F using six heating banks with biasing control to balance any temperature gradients.

The furnace is constructed with high-quality refractory insulation. It has a venturi cooling blower that aids in cooling, and is controlled by a Eurotherm program control with overtemperature protection. There is also a programmable flow panel to manage the nitrogen flow throughout the process.

The parts are a ceramic matrix composite (CMC), which is a series of ceramic threads that are bound together and woven by a 3D printing system. These parts can be made into very intricate aircraft sub-assemblies for the smaller units as well as large engine parts. For more information, see our ‘What Are CMCs?‘ article.

The parts are heated to 1,220°F in a retort chamber that is pressurized with nitrogen. The byproducts of the outgassing part are directed by pressure and flow out of the rear of the furnace. After de-bindering, the parts are heated in a vacuum furnace to temperatures in excess of 2,300°F. The result is a super-strong component that is more resilient and lighter than titanium.

All L&L furnaces can be configured with various options and be specifically tailored to meet your thermal needs. We also offer furnaces equipped with pyrometry packages to meet ASM2750E and soon-to-be-certified MedAccred guidelines.

Options include a variety of control and recorder configurations. A three-day, all-inclusive startup service is included with each system within the continental US and Canada. International startup and training service is available by factory quote.

If precise temperature control and uniformity is key to your process, then L&L’s XLC series is a great choice. Please be sure to visit our new website at www.llfurnace.com.

FOR MORE INFORMATION, CONTACT:

Thomas Schultz, Sales Manager Phone: (610) 459-9216

L&L Special Furnace Co., Inc. FAX: (610) 459-3689

P.O. Box 2129 Email: [email protected]

Aston, PA 19014 Web: www.llfurnace.com