The beauty and elegance of heat-treated steel don’t stop at the metal’s surface; they can also be seen in the elaborate crystalline structures that give the metal its distinctive characteristics.

In this article, we’ll examine the nature of steel crystalline structures, as well as the properties that are found in various kinds of steel after heat treatment.

Understanding Steel Crystalline Structures

In their solid state, metals are made up of crystallized lattice structures, which are usually referred to in a more general way as the metal’s “crystalline structure.”

The atoms that make up this special crystalline structure can vary, though stainless steel is predominantly composed of iron atoms, as well as some carbon and small amounts of other metals depending on the type.

Steel crystalline structures first emerge during solidification. In its liquid form, iron is not crystalline at all. However, as the molten metal begins to cool, crystals will gradually start to form.

As the metal undergoes multiple temperature stages, various types of crystals are formed. Finished steels will therefore contain trace amounts of ferrite, austenite, and cementite.

What makes steel crystalline structures so different from each other? These structures will differ based on the amount of carbon that they can absorb.

Ferritic Steel

Ferritic crystalline structures only contain a small amount of carbon, roughly 0.025%. This makes ferritic steel extremely soft and ductile, though the lack of carbon also means that ferritic steel has low resistance to corrosion.

Additionally, ferritic steel has average strength, which means that it is not recommended for use within high-temperature settings.

Properties of Ferritic Steel

The reason that ferritic steel absorbs so little carbon is because of the limits of the geometry of its crystalline structure. Ferritic steel crystalline structure is characterized by a cube-shaped arrangement, which places an iron atom at each corner and one in the center. It is this arrangement that also gives ferritic steel its distinctive magnetic properties.

Uses of Ferritic Steel

Since it’s not the strongest form of steel, ferritic steel does not see a great deal of use. However, in some cases, ferritic steel can be combined with other elements (such as chromium) to increase its durability and corrosion resistance.

It’s not uncommon to find ferritic steel in the following applications:

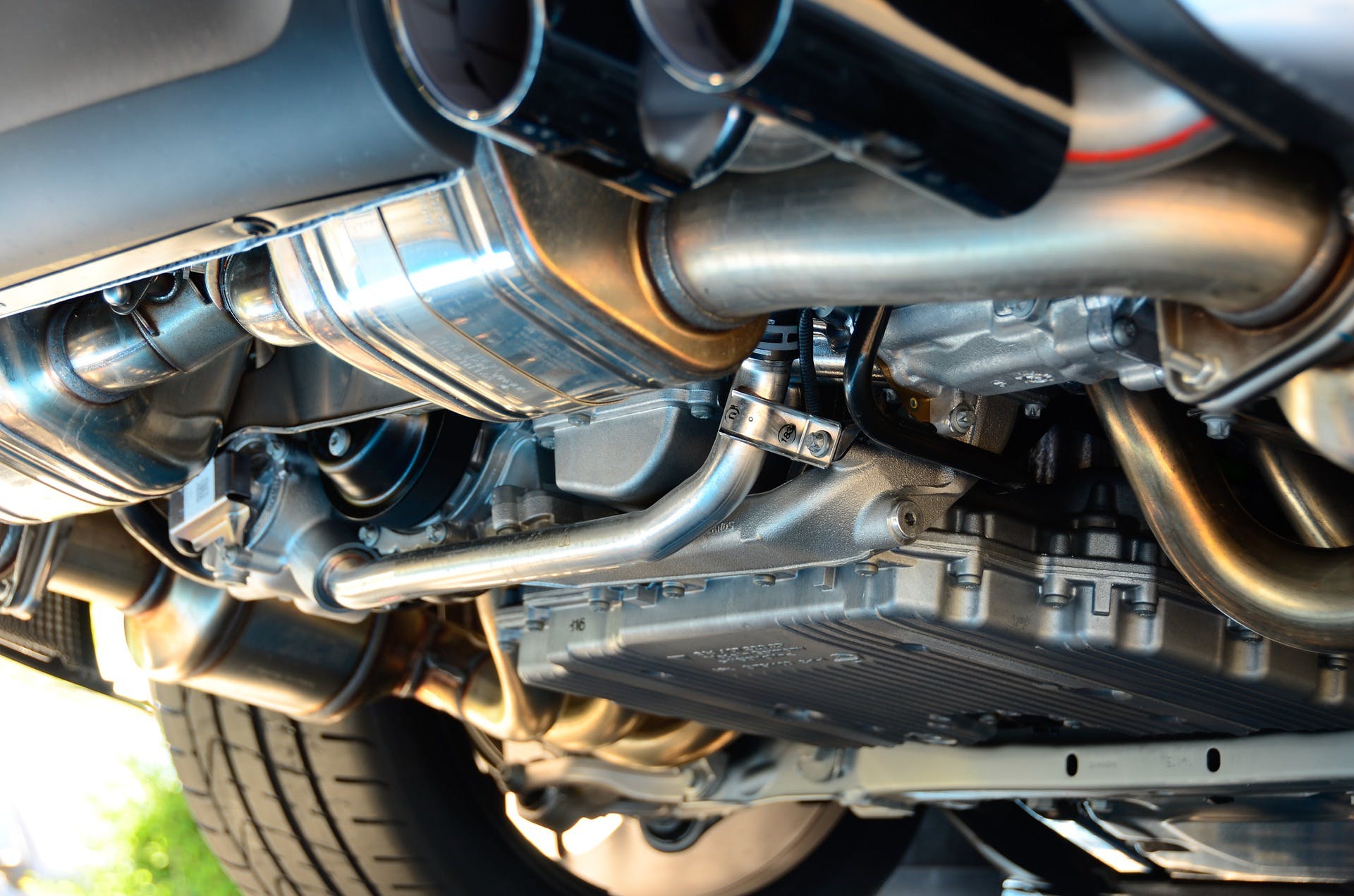

- Automotive exhaust systems

- Food equipment and appliances

- Heat exchangers

- Appliances

Larger applications rely on other forms of steel for greater durability.

Austenitic Steel

Austenite is a form of iron that can absorb more carbon than ferrite. Austenite can be derived from ferrite by subjecting it to extreme temperatures (1,000°C or more), which will allow its body-centered cubic crystal structure to transition to a face-centered structure.

Properties of Austenite

These face-centered steel crystalline structures allow austenite to absorb up to 2% carbon, considerably more than ferritic steel.

Unfortunately, as austenite cools, it reverts back to its ferritic form. However, the steel can be forced to retain its structure by adding additional metals, such as nickel and manganese. This ensures that austenite retains its structure and properties even at low temperatures.

Austenite steel also tends to be easier to weld than other forms of steel. This makes austenite a bit more versatile and affordable since different pieces of steel can be made separately and then welded together at a later time.

Uses of Austenite

Because of the durability of austenite, it is one of the most commonly used forms of stainless steel.

The metal in your stainless steel screws or other hardware is almost always a form of austenite. This metal is used for its relative durability and high resistance to corrosion.

Resistance to corrosion also makes austenite an ideal choice for food, pharmaceutical, and petrochemical applications. Certain types of furniture can also be made from austenite steel. This steel can even be used for some types of metalwork.

Martensitic Steel

When high-temperature austenite is quickly quenched, carbon atoms become trapped in the steel crystalline structures. When this happens, martensite is created.

Properties of Martensite

The steel crystalline structures in martensite contain relatively high levels of carbon, which makes this metal extremely strong and resistant to fracture. Its low ductility (its ability to be bent or twisted into wire) also makes this a strong and durable form of steel.

Additionally, martensite can be held at relatively low temperatures for varying lengths of time in a process called tempering. Tempering reduces strength while improving toughness and ductility. This allows martensite to be worked and adapted for a wide variety of applications.

Uses of Martensite

Because martensite is so stable and strong, it is an ideal material for cutlery, knives, and other high-quality kitchen implements. But outside of the kitchen, martensite also has applications in the medical field, as well as in the aerospace industry.

The exact application of martensitic steel will depend on the carbon content acquired during the metallurgical process.

Type 410 stainless steel can be a multi-purpose material that’s well-suited for hardware, gun parts, turbine blades, and machine parts. Type 440 stainless steel offers greater hardness, which can be ideal for blades since they won’t have to be sharpened as often. You can expect to find Type 440 steel in kitchen cutlery and medical instruments.

Conclusion

The configuration of steel crystalline structures will influence a metal’s ability to absorb carbon. This has a great impact on the overall quality and durability of the finished product.

The most common forms of steel crystalline structures include ferritic, austenitic, and martensitic steel, though austenitic and martensitic steel have a wider range of applications due to their higher strength and durability.

Reliable Heat Treatment Near Me

L&L Special Furnace Co. understands the chemical and mechanical processes associated with heat-treated steel. We’re proud of our longstanding reputation when it comes to industrial furnaces, ovens, kilns, quench tanks, and other heat-treating systems.

We have a passion for innovation and quality workmanship. You can find our facilities located just south of Philadelphia, PA, though we provide sales and service of equipment worldwide.

Contact us for your heat treatment needs, and we can partner with you to provide affordable, reliable service.