L&L Special Furnace Co., Inc. has shipped a floor-standing, high-temperature silicon carbide furnace to a leading worldwide supplier of high-temperature piezo ceramics used in the military, aerospace, and medical fields.

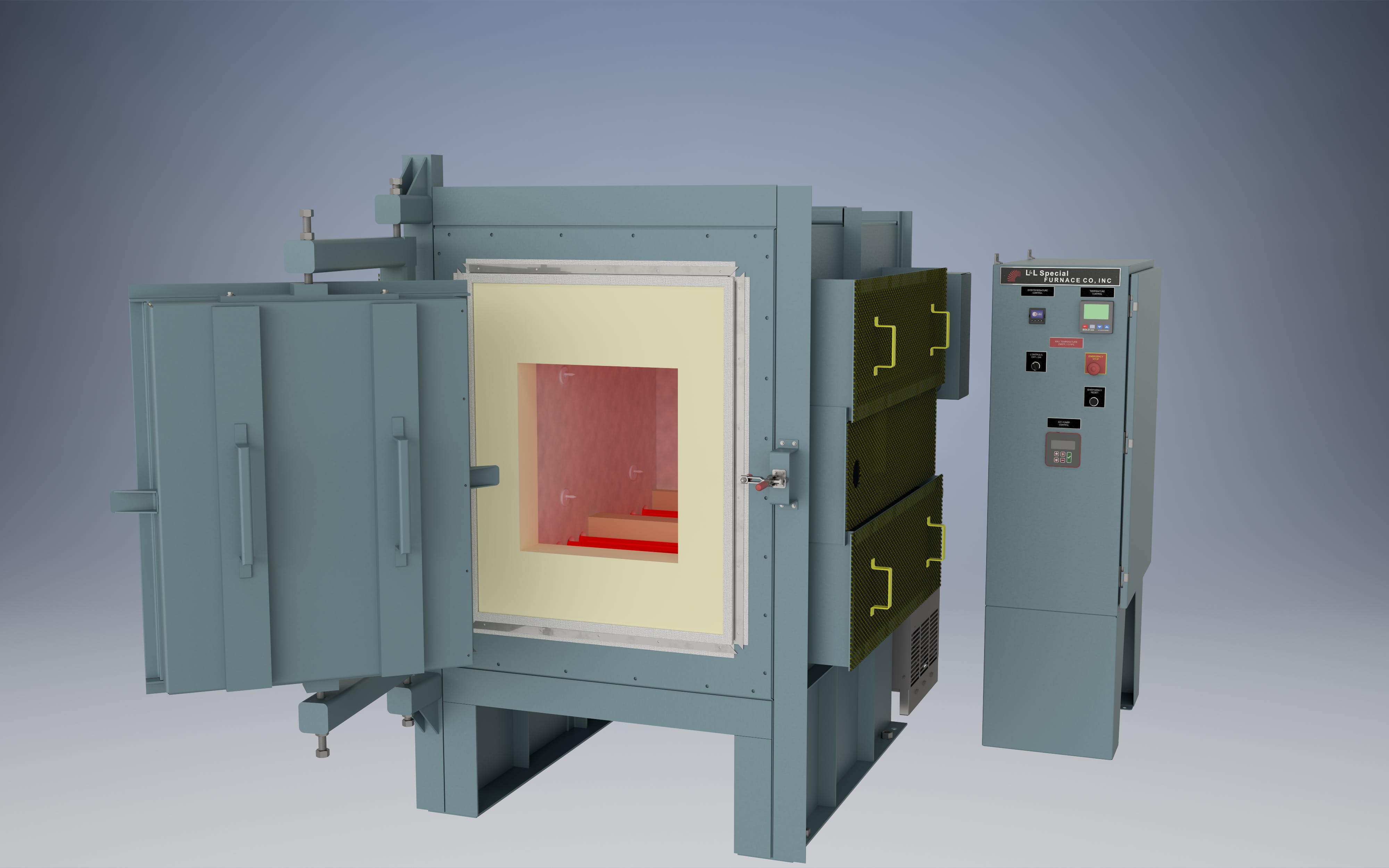

The L&L model GLF836 has an effective work zone of 18” wide by 18” high by 36” deep. The furnace has a double pivot horizontal door. It is used for processing glass products to 2,500°F / 1,371°C. This process causes lead to outgas from the process. The furnace interior is constructed from high-alumina refractory with less silica than normal linings, which helps delay the corrosive reaction between the silica present in the refractory and the lead outgassing at elevated temperatures. There is also a removable layer of recrystallized alumina fiber board in the hot zone. This sacrificial high-alumina board can be removed and easily replaced, which helps maintain the furnace chamber integrity.

The furnace is powered by high-density, silicon-carbide elements located above and below the furnace hearth. It is controlled by a SOLO single-set point control with overtemperature protection. A tap transformer is included with multiple taps to adjust the primary element voltage as needed as the heating elements change in resistance. An SCR power control with soft start regulates the output voltage to the elements.

The model GLF836 features a free-standing NEMA12 control panel with fused disconnect and Type R thermocouple for instrumentation. The furnace is also constructed to NFPA86 guidelines for safety.

Options include a variety of control and recorder configurations. A three-day, comprehensive startup service can be included with each system within the continental US and Canada. International startup and training service is available by factory quote.

If precise temperature control and uniformity are key to your process, then L&L’s GLF series is a great choice. Contact us today for more information.