L&L Special Furnace Co., Inc., has shipped a medium-sized, high-temperature box furnace to a government military defense organization located in the southeastern United States. The furnace is used for military ceramic composite development along with research and development for various other components.

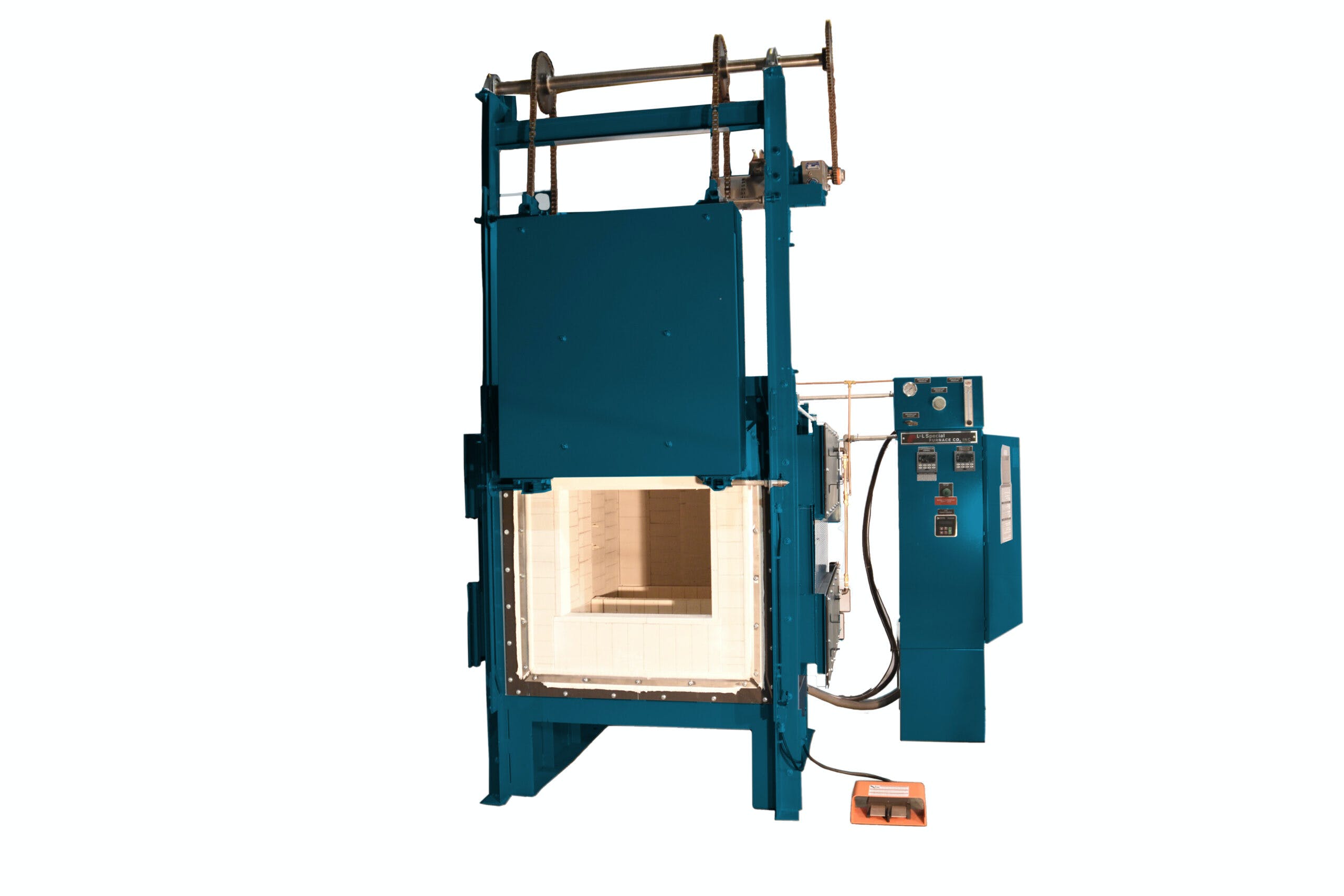

The furnace has a working zone of 24” wide by 18” high by 36” deep. The furnace is rated for continuous operating temperatures up to 2500°F / 1371°C.

The furnace comes equipped with silicon carbide heating elements for high-temperature operation. The furnace case is sealed from the inside out for use with inert “blanketing gas’. Included is an atmosphere flow panel with a flowmeter. The hearth is alumina plates supported on the bottom with hard fire brick. The door is an electric vertical counterbalanced door. Included is a step down transformer to control secondary element voltage. The furnace thermocouples are type S and the furnace is approved by an independent 3 rd party testing facility to ensure the equipment meets all EHS and current safety standards.

The furnace is controlled by a Honeywell program control and corresponding overtemperature protection. The furnace also has heat shields to ensure that the case temperature is below 120°F. A spare set of elements and thermocouples are included to minimize any unforeseen downtime.

All L&L furnaces can be configured with various options and be specifically tailored to meet your thermal needs. L&L also offers furnaces equipped with pyrometry packages to meet ASM2750E and soon to be certified MedAccred guidelines.

Options include a variety of control and recorder configurations. A three-day, all-inclusive startup service is offered with each system within the continental US and Canada. International startup and training service is available by factory quote.

If precise temperature control and uniformity is key to your process, then L&L’s GL / GLF series is a great choice. Contact us today for more information.