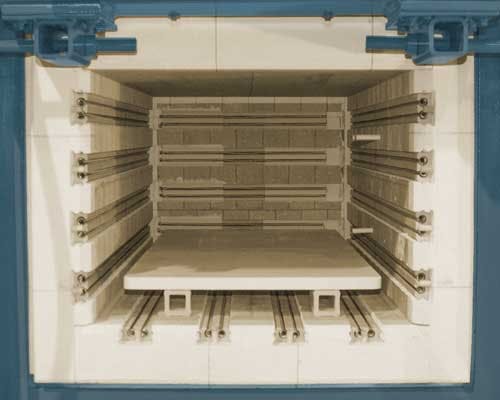

The high uniformity of the XLE Series makes it a staple in the heat treating industry. It's the perfect box furnace solution for your hardening, solution heat treating, stress relieving, annealing, aging, precipitation hardening, and tempering needs. In the ceramics field, the XLE Series is a reliable, precision-controlled workhorse, promising repeatable results in ceramic bisque firing, thin film processing, glazing, and decorating. Other industries rave about its excellence in everything from brazing, calcining, and drying, to the melting of glass and metals, glass annealing and bending, enameling, and sintering. Although we have many "standard" configurations, XLE Series furnaces are available in a number of custom sizes and options to suit specific needs, including: Vertical Doors, Fans, Cooling Venturis, Vents, Special Hearths, Racks, Baskets / Loading Devices, Quenching Systems, Controlled Atmospheres, Retorts, Viewing Ports, Element Alloys, Thermocouples, Alarms, Program Controls, & Recorders