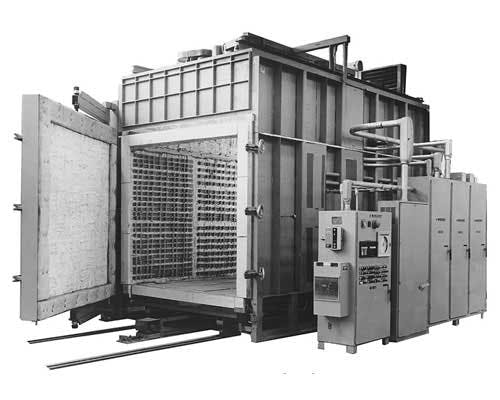

The FC Series are ceramic fiber lined car bottom furnaces. They feature tight pneumatic car seals, electric car drives and a wide range of custom options including electric and pneumatic vertical doors, fans, zoning, program controls and custom hearths. The car bottom makes these furnaces extremely easy to load. They achieve high precision by featuring highly accurate controls, solid state contactors or SCR power controls, fans, multi-zoning, and very even spacing of elements for uniformity. Gas versions feature high velocity multi-zoned burners. Gas versions can reach 2400ºF (1300°C). Electric versions reach 2200°F (1200°C) with iron-aluminum-chrome elements, and up to 2000°F (1095°C) with the standard nickel-chrome elements. Insulation is all ceramic fiber except for hearth and hearth support. These furnaces can be designed for extremely heavy loads. Gas fired units are also available.